The Principles of Material Selection for Machine Parts

- Share

- Issue Time

- Sep 23,2021

Summary

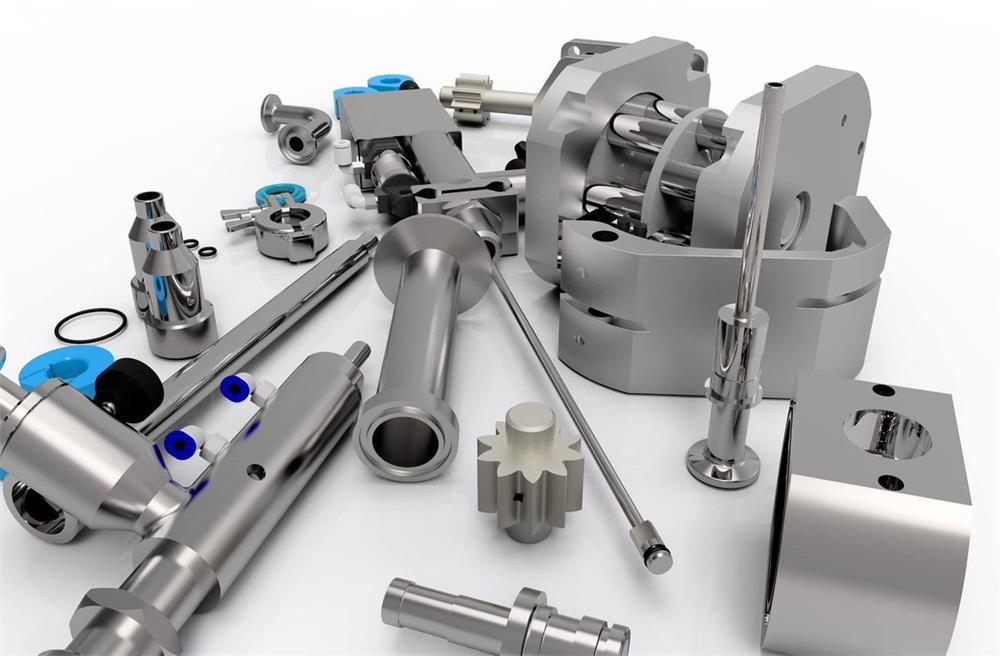

The most important thing about machine parts is performance, which often depends on what materials they are made of. This article will specifically introduce the principles of material selection for machine parts.

Machine parts are the basic components that make up the machine and are inseparable individual parts. The use performance of the selected materials for machine parts should be able to meet the requirements of the use of parts, durable, easy to process, and low cost. That needs to be considered from the following aspects.

1. Requirements for use (primary consideration)

(1) The working conditions of the parts (vibration, shock, high temperature, low temperature, high speed, the high load should be treated with caution)

(2) Restrictions on the size and quality of parts

(3) The importance of the parts (relative importance to the reliability of the whole machine)

2. Process requirements

(1) Blank manufacturing (casting, forging, cutting)

(2) machine processing

(3) Heat treatment

(4) Surface treatment

3. Economic requirements

(1) Material price (comparison between the cost of blanks and processing costs of ordinary round steel and cold-drawn sections, precision casting, and precision forging);

(2) Processing batch size and processing cost;

(3) Utilization rate of materials (such as the specifications of plates, bars, and profiles);

(4) Alternatives (Try to use cheap materials to replace relatively expensive rare materials. For example, in some wear-resistant parts, use ductile ink instead of copper sleeves, and oil-bearing bearings instead of turning parts. When the speed load is not large, use Nylon replaces steel gears or copper worm gears, etc).

4. The basic requirements for the design of machine parts

(1) Work normally and reliably within the scheduled working period to ensure the various functions of the machine;

(2) To minimize the production and manufacturing costs of parts;

(3) Use common standard parts in the market as much as possible;

(4) For products that may be serialized, consider the versatility of parts as much as possible at the beginning of the design, and if they are not universal, they should be similar in structure as much as possible to reduce the workload of the manufacturing process layout and fixture design.

For important parts or mass-produced parts, tests should be carried out to check whether the selected materials and heat treatment methods can meet the performance requirements. After the test results meet the requirements, mass production can be performed.

Only by considering the above-mentioned basic material selection considerations for machine parts, it can be ensured that the appropriate materials are selected for machine parts and the excellent properties are exerted. If you want to know more about machine parts after reading the above, you can get a comprehensive solution by contacting us.

As a professional parts manufacturer, we have accumulated rich manufacturing experience in this field. We have a standardized production team and strict quality inspection system, which can control the quality of products in all aspects. We also provide effective solution technology and thoughtful one-stop service according to the needs of customers. If you are interested in our machine parts, please contact us immediately!