What Are the Requirements for the Realization of Manufacturability and Standardization of Machine Parts?

- Share

- Issue Time

- Mar 8,2022

Summary

This article will specifically share the requirements for the realization of manufacturability and standardization of machine parts for your reference.

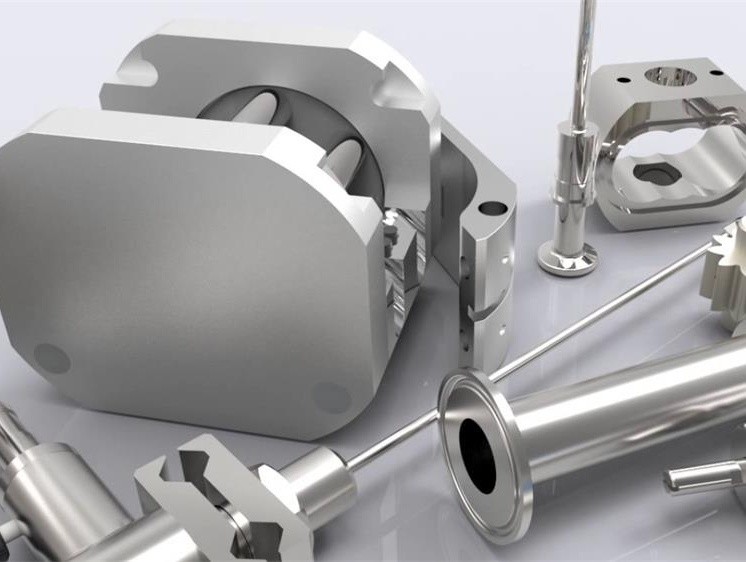

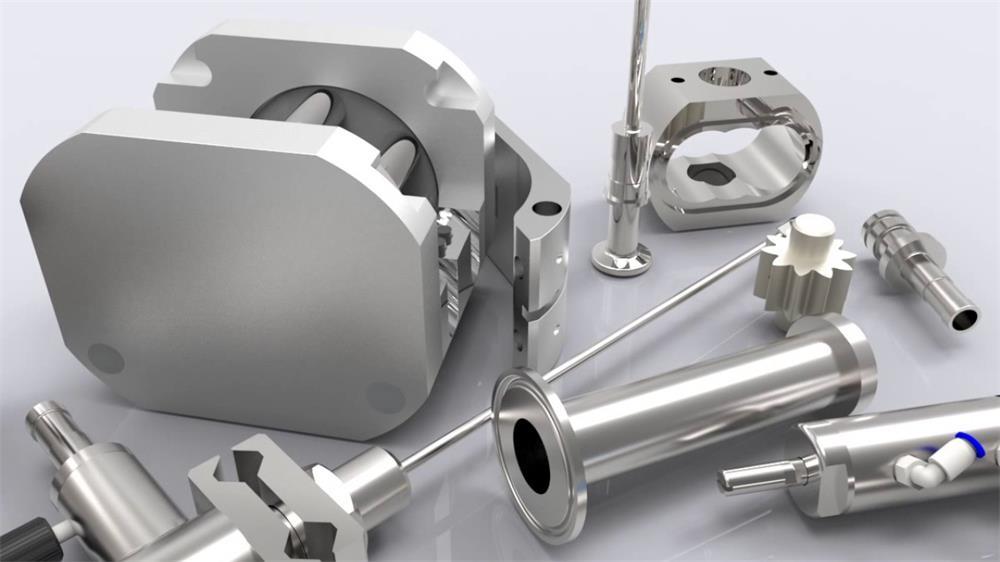

When designing machine parts, it should not only meet the requirements of use, that is, have the required working capacity, but also meet the production requirements, otherwise it may not be manufactured, or although it can be manufactured, the labor and materials are very uneconomical. Under specific production conditions, if the designed machine parts are easy to process and the processing cost is low, such parts are said to have good manufacturability.

Basic requirements for manufacturability:

(1) Rational selection of blanks

The methods of blank preparation in machine manufacturing include direct use of profiles, casting, forging, stamping, and welding. The selection of the blank is related to the specific production technical conditions and generally depends on the production batch, material properties, and processing possibilities.

(2) Simple and reasonable structure

When designing the structural shape of the part, it is advisable to use the simplest surface (such as plane, cylindrical surface, helical surface) and its combination, and at the same time, try to minimize the number of machined surfaces and the minimum machining area.

(3) Specify the appropriate manufacturing accuracy and surface roughness

The processing cost of parts increases with the increase in accuracy, especially in the case of high accuracy, this increase is extremely significant. Therefore, high precision should not be pursued without sufficient grounds. In the same way, the surface roughness of the parts should also be properly specified according to the actual needs of the mating surface.

Basic requirements for standardization:

Standardization refers to the whole process of activities with the formulation and implementation of standards as the main content. The research field of standardization is very broad. As far as industrial product standardization is concerned, it refers to the formulation and implementation of standards for product variety, specifications, quality, inspection or safety, and hygiene requirements.

Product standardization itself includes three meanings:

(1) Serialization of product varieties and specifications-the main parameters, types, sizes, basic structures, etc. of the same type of products are classified into series in order to make serialized products to meet the extensive needs of users with fewer varieties and specifications;

(2) Generalization of parts and components - the same type or different types of products with similar use and structure (such as bolts, bearing seats, couplings, reducers, etc.) are unified to achieve general exchange;

(3) Standardization of product quality - product quality is the "lifeline" of all enterprises. To ensure qualified and stable product quality, it is necessary to do a good job in the standardization of design, processing technology, assembly inspection, and even packaging, storage, and transportation.

The standardization of products is of great significance: in terms of manufacturing, specialized products can be implemented, which can improve product quality and reduce costs; in terms of design, it can reduce the design workload; in terms of management and maintenance, it can reduce inventory and facilitate.

In order to ensure that the components can work properly during the specified working conditions and service life, the following requirements must be met:

1. Having sufficient strength to ensure that the component will not be damaged under the action of external force is a prerequisite for the component to work normally. Therefore, the strength of the component refers to the ability of the component to resist damage under the action of external force.

2. The deformation of the member with sufficient rigidity under the action of external force should be within the allowable limit. The ability of a component to resist deformation under the action of external force is the stiffness of the component.

3. Sufficient stability. When the axial pressure reaches a certain value, some slender rods (or thin-walled members) will lose their original balance and lose their working ability. This phenomenon is called instability.

The so-called stability refers to the ability of the component to maintain the original shape balance. The strength, stiffness, and stability of components are related to the machine properties of the materials used, which must be determined by experiments.

If you want to know more about machine parts after reading the above, please refer to the previous news.

We are an experienced parts manufacturer. We have leading R&D technology and excellent manufacturing technology and can control the quality of products in all aspects. Our products are used in various machinery and equipment and have excellent application performance in all walks of life. Our thoughtful after-sales service has also received unanimous praise from customers all over the world. If you want to buy our machine parts, please contact us immediately!